09

мар

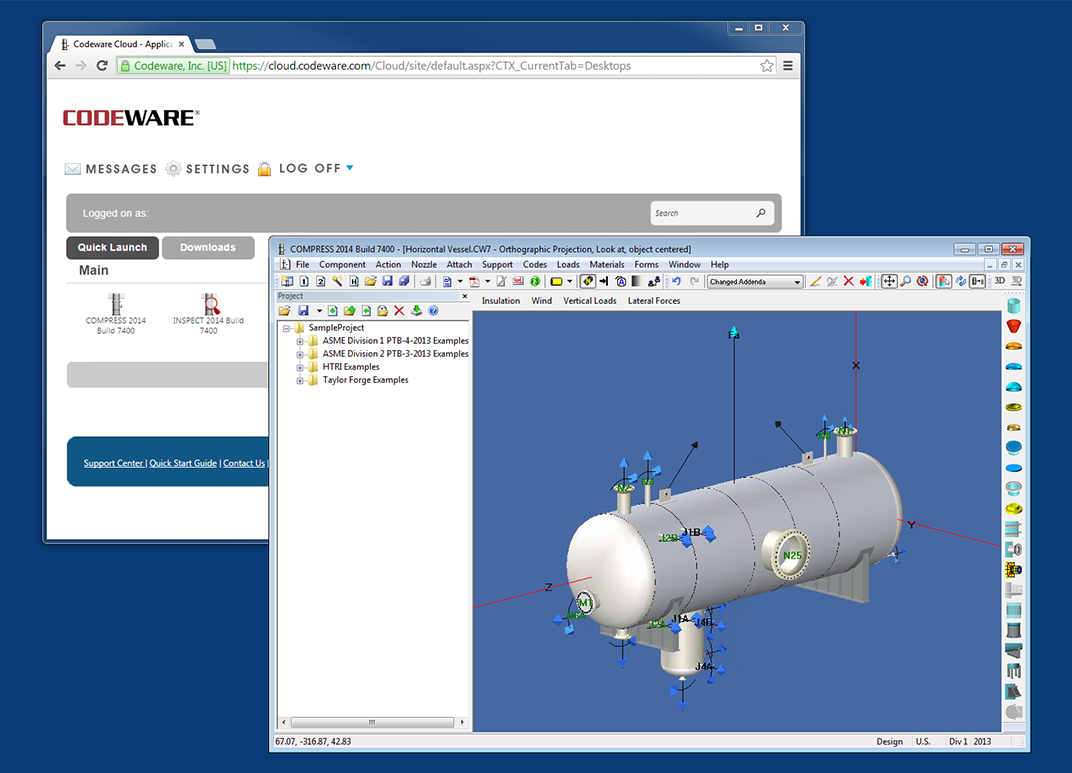

CODEWARE Support Center. COMPRESS 2016 Build 7600 New Features Back to Top. Bill of Materials; Bill of Materials report. It is safe to run the calculations while multiple instances of COMPRESS are open as long as only one TEMA 9th FEA calculation is being performed at any given time. Running two TEMA 9th FEA. Becht Engineering is excited to be partnering with Codeware, Inc. To present this 4-day COMPRESS software training.This course provides comprehensive instruction on the COMPRESS Heat Exchanger Wizard dialog windows for the mechanical design of shell and tube heat exchangers.

Highlights • Bill of Materials • • • Bolted Covers • • • General • • New Features • ASME/ANSI Flanges • • • Elbow Connections • • • General Options • • • Nozzles • • • • Set Mode Options F7 • • • • • Support Lugs • • • Toolbars • • • XML • • • Highlights • Bill of Materials • • Bill of Materials report A new Bill of Materials report may be activated from the Set Mode Options -> Reporting -> How to install gm mdi manager etas. Bill of Materials Report page. When the Detailed report format option is active, the bill of materials includes separate tables for main component categories with individual columns for detailed data. When the Detailed report format option is inactive, the bill of materials is a single table with columns for item, quantity, and description. The Set Mode Options page also includes options to set an item prefix value for the various component types as well as a percent material allowance to account for forming, cutting, and drop. [56877] • Bolted Covers • • UG-34 bolted cover option for ASME B16.5/16.47 flanges The ability to add UG-34 (Division 2 Part 4.6) bolted covers to ASME B16.5/16.47 flanges is now available inside of the Select ASME B16.5/16.47 Flange dialog. This feature allows the design of nozzle openings in bolted covers on standard flanges. [8648] • General • • ASME Section VIII, Division 1 2015 Edition The 2015 Edition of the ASME Code is now available.

The additions and changes follow: (1) The materials database now includes all ASME Section II, Part D 2015 Edition data for both Customary and Metric editions. This includes all materials from Tables 1A, 1B and 3. In addition, Table U (tensile strength), Table Y-1 (yield strength), Tables TE-1 through TE-5 (thermal expansion coefficients), Tables TM-1 through TM-5 (elastic moduli) and all vacuum charts have been updated.

(2) Table U-3 Year of Acceptable Edition of Referenced Standards: ASME B16.5 2013 Pipe Flanges and Flanged Fittings NPS ½ Through NPS 24 is now used for designs with 2015 Edition or later. All pressure-temperature ratings and material groups are now updated to reflect the 2013 Edition. (3) UG-32 Formed Heads, and Sections, Pressure on Concave Side: Paragraph references updated to reflect the restructuring of UG-32.

Lenovo firmware a369. (4) UG-37 Reinforcement Required For Openings in Shells and Formed Heads: Welded pipe and tubing now use the corresponding seamless product form allowable stress for the nozzle and/or vessel. (5) UG-40(e) Limits of Reinforcement: An error deficiency is now reported when the radial limit of reinforcement falls on a flat head or tubesheet. (6) UCS-56 Requirements for Postweld Heat Treatment: The postweld heat treatment exemption for SA-202 Grade A and B in Table UCS-56-3 has been removed. (7) UCS-66 Materials • UCS-66(a): Paragraph references updated to reflect the restructuring of UCS-66(a). • UCS-66(f): Impact testing is now enforced for all materials with a minimum yield strength greater than 65 ksi (450 MPa).

• Figure UCS-66 and Figure UCS-66M: Impact test exemption curves updated to reflect changes to Note (3)(a). (8) Table UNF-79 Postfabrication Strain Limits and Required Heat Treatment: Temperature limits and forming strain limits added for Alloys N06022, N06601, N06625, N06690. (9) Table UHA-32-7 Postweld Heat Treatment Requirements for High Alloy Steels: Postweld heat treatment requirements for P-No. 45 materials have been added. (10) U-5 form updated.

[56785] New Features • ASME/ANSI Flanges • • Integral flange ASME B16.5 material without ASME equivalent A warning is now reported in the Deficiencies Summary when an ASME B16.5/B16.47 material has no exact ASME Section II, Part D material match. The warning reports the original material and the substituted material. The specified replacement material is chosen in the Nozzle dialog. [57283] • Elbow Connections • • Minimum thickness per UG-16(b) Elbow and nozzle piping components now include a UG-16(b) thickness check. A deficiency is reported if the component does not meet the thickness specified in UG-16.

[56853] • General Options • • Vessel tag information A class and associated category may now be specified for the vessel tag in the Set Vessel General Info dialog, which is relocated from the Action -> Reports menu to the Action toolbar menu. This information is stored in the XML output and may be included on the cover page. [56875] • Nozzles • • Physical interference check for nozzles in flat heads The physical interference check for nozzles in flat heads is now active for Division 1 files with Code Case 2695 active and for Division 2 files. [56783] • Service input now available in the Nozzle dialog A new input for nozzle service is available in the Nozzle dialog that is included in the XML and XML3D formats. In addition, a new option switch is now available in the Form Settings and Defaults dialog to use the nozzle service instead of the nozzle identifier in the Purpose field of ASME A-Forms and U-Forms. [56874] • Set Mode Options F7 • • Design pressure reporting switch for the Nozzle Summary A new reporting option, Report Nozzle Summary At Design Pressure, is now available on the Set Mode Options -> Reporting -> General page which controls whether the results are reported at the design pressure or the maximum rated pressure. [57407] • Flange option for seamless forged nozzle type nomenclature A new option on the Set Mode Options -> Defaults -> Flanges page allows the choice of FVC or FCI nomenclature for seamless nozzle forgings.

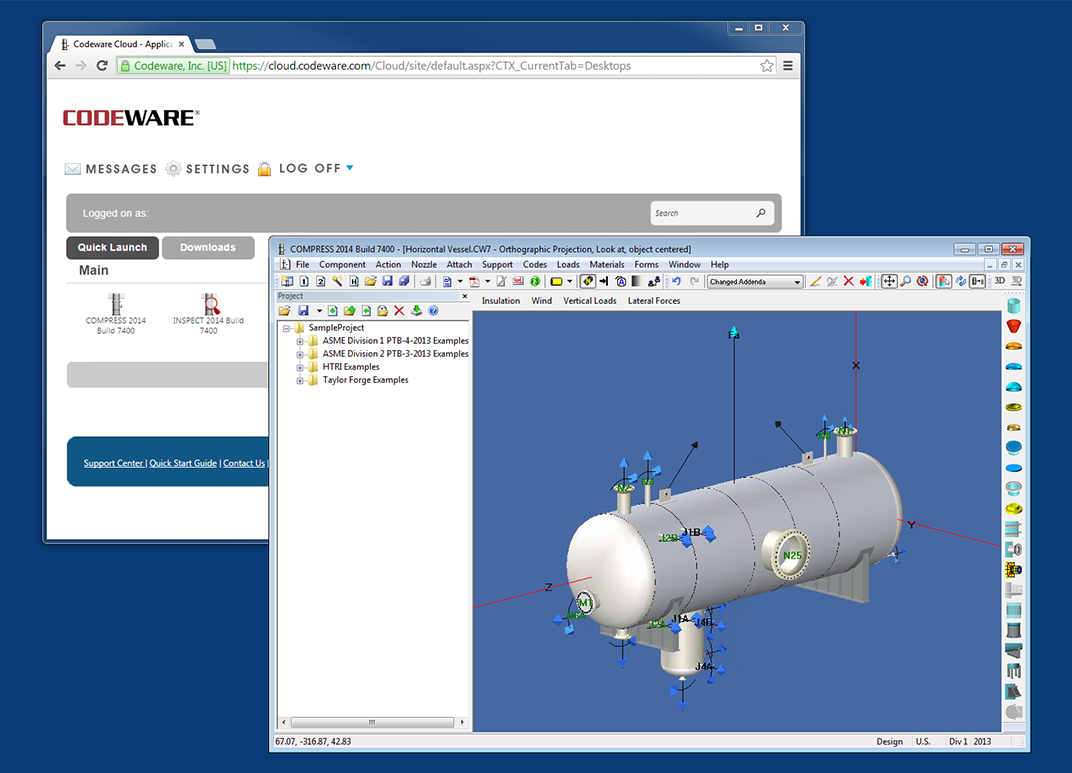

CODEWARE Support Center. COMPRESS 2016 Build 7600 New Features Back to Top. Bill of Materials; Bill of Materials report. It is safe to run the calculations while multiple instances of COMPRESS are open as long as only one TEMA 9th FEA calculation is being performed at any given time. Running two TEMA 9th FEA. Becht Engineering is excited to be partnering with Codeware, Inc. To present this 4-day COMPRESS software training.This course provides comprehensive instruction on the COMPRESS Heat Exchanger Wizard dialog windows for the mechanical design of shell and tube heat exchangers.

Highlights • Bill of Materials • • • Bolted Covers • • • General • • New Features • ASME/ANSI Flanges • • • Elbow Connections • • • General Options • • • Nozzles • • • • Set Mode Options F7 • • • • • Support Lugs • • • Toolbars • • • XML • • • Highlights • Bill of Materials • • Bill of Materials report A new Bill of Materials report may be activated from the Set Mode Options -> Reporting -> How to install gm mdi manager etas. Bill of Materials Report page. When the Detailed report format option is active, the bill of materials includes separate tables for main component categories with individual columns for detailed data. When the Detailed report format option is inactive, the bill of materials is a single table with columns for item, quantity, and description. The Set Mode Options page also includes options to set an item prefix value for the various component types as well as a percent material allowance to account for forming, cutting, and drop. [56877] • Bolted Covers • • UG-34 bolted cover option for ASME B16.5/16.47 flanges The ability to add UG-34 (Division 2 Part 4.6) bolted covers to ASME B16.5/16.47 flanges is now available inside of the Select ASME B16.5/16.47 Flange dialog. This feature allows the design of nozzle openings in bolted covers on standard flanges. [8648] • General • • ASME Section VIII, Division 1 2015 Edition The 2015 Edition of the ASME Code is now available.

The additions and changes follow: (1) The materials database now includes all ASME Section II, Part D 2015 Edition data for both Customary and Metric editions. This includes all materials from Tables 1A, 1B and 3. In addition, Table U (tensile strength), Table Y-1 (yield strength), Tables TE-1 through TE-5 (thermal expansion coefficients), Tables TM-1 through TM-5 (elastic moduli) and all vacuum charts have been updated.

(2) Table U-3 Year of Acceptable Edition of Referenced Standards: ASME B16.5 2013 Pipe Flanges and Flanged Fittings NPS ½ Through NPS 24 is now used for designs with 2015 Edition or later. All pressure-temperature ratings and material groups are now updated to reflect the 2013 Edition. (3) UG-32 Formed Heads, and Sections, Pressure on Concave Side: Paragraph references updated to reflect the restructuring of UG-32.

Lenovo firmware a369. (4) UG-37 Reinforcement Required For Openings in Shells and Formed Heads: Welded pipe and tubing now use the corresponding seamless product form allowable stress for the nozzle and/or vessel. (5) UG-40(e) Limits of Reinforcement: An error deficiency is now reported when the radial limit of reinforcement falls on a flat head or tubesheet. (6) UCS-56 Requirements for Postweld Heat Treatment: The postweld heat treatment exemption for SA-202 Grade A and B in Table UCS-56-3 has been removed. (7) UCS-66 Materials • UCS-66(a): Paragraph references updated to reflect the restructuring of UCS-66(a). • UCS-66(f): Impact testing is now enforced for all materials with a minimum yield strength greater than 65 ksi (450 MPa).

• Figure UCS-66 and Figure UCS-66M: Impact test exemption curves updated to reflect changes to Note (3)(a). (8) Table UNF-79 Postfabrication Strain Limits and Required Heat Treatment: Temperature limits and forming strain limits added for Alloys N06022, N06601, N06625, N06690. (9) Table UHA-32-7 Postweld Heat Treatment Requirements for High Alloy Steels: Postweld heat treatment requirements for P-No. 45 materials have been added. (10) U-5 form updated.

[56785] New Features • ASME/ANSI Flanges • • Integral flange ASME B16.5 material without ASME equivalent A warning is now reported in the Deficiencies Summary when an ASME B16.5/B16.47 material has no exact ASME Section II, Part D material match. The warning reports the original material and the substituted material. The specified replacement material is chosen in the Nozzle dialog. [57283] • Elbow Connections • • Minimum thickness per UG-16(b) Elbow and nozzle piping components now include a UG-16(b) thickness check. A deficiency is reported if the component does not meet the thickness specified in UG-16.

[56853] • General Options • • Vessel tag information A class and associated category may now be specified for the vessel tag in the Set Vessel General Info dialog, which is relocated from the Action -> Reports menu to the Action toolbar menu. This information is stored in the XML output and may be included on the cover page. [56875] • Nozzles • • Physical interference check for nozzles in flat heads The physical interference check for nozzles in flat heads is now active for Division 1 files with Code Case 2695 active and for Division 2 files. [56783] • Service input now available in the Nozzle dialog A new input for nozzle service is available in the Nozzle dialog that is included in the XML and XML3D formats. In addition, a new option switch is now available in the Form Settings and Defaults dialog to use the nozzle service instead of the nozzle identifier in the Purpose field of ASME A-Forms and U-Forms. [56874] • Set Mode Options F7 • • Design pressure reporting switch for the Nozzle Summary A new reporting option, Report Nozzle Summary At Design Pressure, is now available on the Set Mode Options -> Reporting -> General page which controls whether the results are reported at the design pressure or the maximum rated pressure. [57407] • Flange option for seamless forged nozzle type nomenclature A new option on the Set Mode Options -> Defaults -> Flanges page allows the choice of FVC or FCI nomenclature for seamless nozzle forgings.

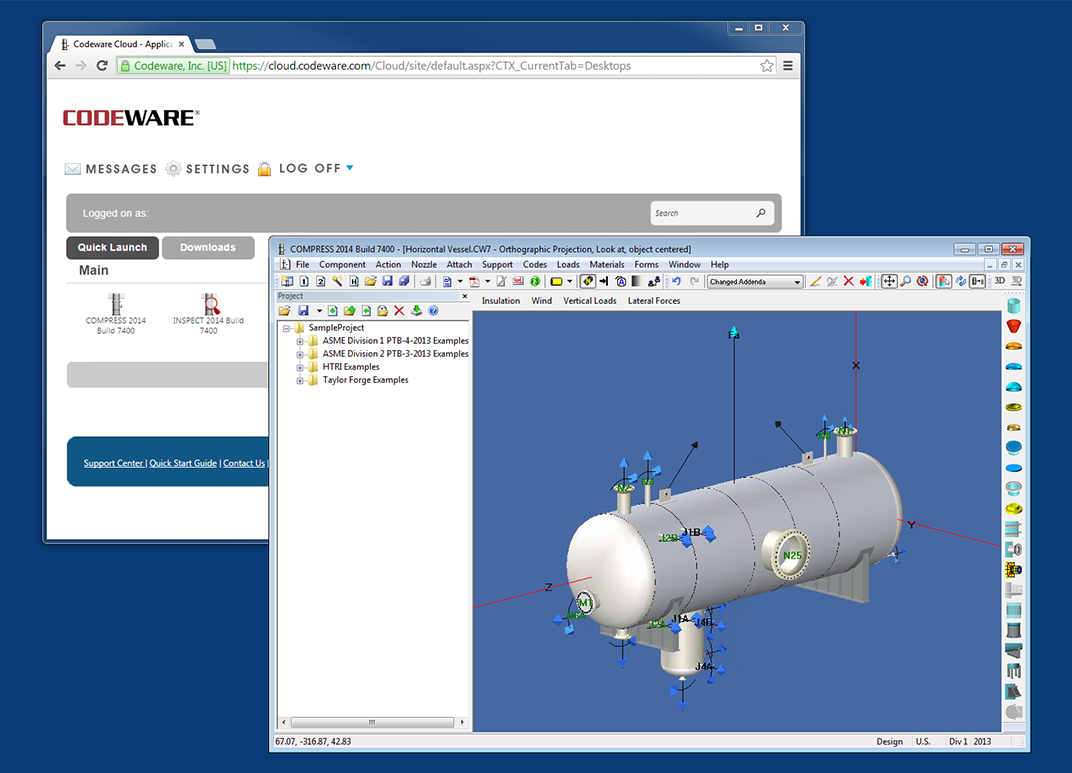

...">Codeware Compress Software Price(09.03.2019)CODEWARE Support Center. COMPRESS 2016 Build 7600 New Features Back to Top. Bill of Materials; Bill of Materials report. It is safe to run the calculations while multiple instances of COMPRESS are open as long as only one TEMA 9th FEA calculation is being performed at any given time. Running two TEMA 9th FEA. Becht Engineering is excited to be partnering with Codeware, Inc. To present this 4-day COMPRESS software training.This course provides comprehensive instruction on the COMPRESS Heat Exchanger Wizard dialog windows for the mechanical design of shell and tube heat exchangers.

Highlights • Bill of Materials • • • Bolted Covers • • • General • • New Features • ASME/ANSI Flanges • • • Elbow Connections • • • General Options • • • Nozzles • • • • Set Mode Options F7 • • • • • Support Lugs • • • Toolbars • • • XML • • • Highlights • Bill of Materials • • Bill of Materials report A new Bill of Materials report may be activated from the Set Mode Options -> Reporting -> How to install gm mdi manager etas. Bill of Materials Report page. When the Detailed report format option is active, the bill of materials includes separate tables for main component categories with individual columns for detailed data. When the Detailed report format option is inactive, the bill of materials is a single table with columns for item, quantity, and description. The Set Mode Options page also includes options to set an item prefix value for the various component types as well as a percent material allowance to account for forming, cutting, and drop. [56877] • Bolted Covers • • UG-34 bolted cover option for ASME B16.5/16.47 flanges The ability to add UG-34 (Division 2 Part 4.6) bolted covers to ASME B16.5/16.47 flanges is now available inside of the Select ASME B16.5/16.47 Flange dialog. This feature allows the design of nozzle openings in bolted covers on standard flanges. [8648] • General • • ASME Section VIII, Division 1 2015 Edition The 2015 Edition of the ASME Code is now available.

The additions and changes follow: (1) The materials database now includes all ASME Section II, Part D 2015 Edition data for both Customary and Metric editions. This includes all materials from Tables 1A, 1B and 3. In addition, Table U (tensile strength), Table Y-1 (yield strength), Tables TE-1 through TE-5 (thermal expansion coefficients), Tables TM-1 through TM-5 (elastic moduli) and all vacuum charts have been updated.

(2) Table U-3 Year of Acceptable Edition of Referenced Standards: ASME B16.5 2013 Pipe Flanges and Flanged Fittings NPS ½ Through NPS 24 is now used for designs with 2015 Edition or later. All pressure-temperature ratings and material groups are now updated to reflect the 2013 Edition. (3) UG-32 Formed Heads, and Sections, Pressure on Concave Side: Paragraph references updated to reflect the restructuring of UG-32.

Lenovo firmware a369. (4) UG-37 Reinforcement Required For Openings in Shells and Formed Heads: Welded pipe and tubing now use the corresponding seamless product form allowable stress for the nozzle and/or vessel. (5) UG-40(e) Limits of Reinforcement: An error deficiency is now reported when the radial limit of reinforcement falls on a flat head or tubesheet. (6) UCS-56 Requirements for Postweld Heat Treatment: The postweld heat treatment exemption for SA-202 Grade A and B in Table UCS-56-3 has been removed. (7) UCS-66 Materials • UCS-66(a): Paragraph references updated to reflect the restructuring of UCS-66(a). • UCS-66(f): Impact testing is now enforced for all materials with a minimum yield strength greater than 65 ksi (450 MPa).

• Figure UCS-66 and Figure UCS-66M: Impact test exemption curves updated to reflect changes to Note (3)(a). (8) Table UNF-79 Postfabrication Strain Limits and Required Heat Treatment: Temperature limits and forming strain limits added for Alloys N06022, N06601, N06625, N06690. (9) Table UHA-32-7 Postweld Heat Treatment Requirements for High Alloy Steels: Postweld heat treatment requirements for P-No. 45 materials have been added. (10) U-5 form updated.

[56785] New Features • ASME/ANSI Flanges • • Integral flange ASME B16.5 material without ASME equivalent A warning is now reported in the Deficiencies Summary when an ASME B16.5/B16.47 material has no exact ASME Section II, Part D material match. The warning reports the original material and the substituted material. The specified replacement material is chosen in the Nozzle dialog. [57283] • Elbow Connections • • Minimum thickness per UG-16(b) Elbow and nozzle piping components now include a UG-16(b) thickness check. A deficiency is reported if the component does not meet the thickness specified in UG-16.

[56853] • General Options • • Vessel tag information A class and associated category may now be specified for the vessel tag in the Set Vessel General Info dialog, which is relocated from the Action -> Reports menu to the Action toolbar menu. This information is stored in the XML output and may be included on the cover page. [56875] • Nozzles • • Physical interference check for nozzles in flat heads The physical interference check for nozzles in flat heads is now active for Division 1 files with Code Case 2695 active and for Division 2 files. [56783] • Service input now available in the Nozzle dialog A new input for nozzle service is available in the Nozzle dialog that is included in the XML and XML3D formats. In addition, a new option switch is now available in the Form Settings and Defaults dialog to use the nozzle service instead of the nozzle identifier in the Purpose field of ASME A-Forms and U-Forms. [56874] • Set Mode Options F7 • • Design pressure reporting switch for the Nozzle Summary A new reporting option, Report Nozzle Summary At Design Pressure, is now available on the Set Mode Options -> Reporting -> General page which controls whether the results are reported at the design pressure or the maximum rated pressure. [57407] • Flange option for seamless forged nozzle type nomenclature A new option on the Set Mode Options -> Defaults -> Flanges page allows the choice of FVC or FCI nomenclature for seamless nozzle forgings.

...">Codeware Compress Software Price(09.03.2019)